Epic Direct Mail

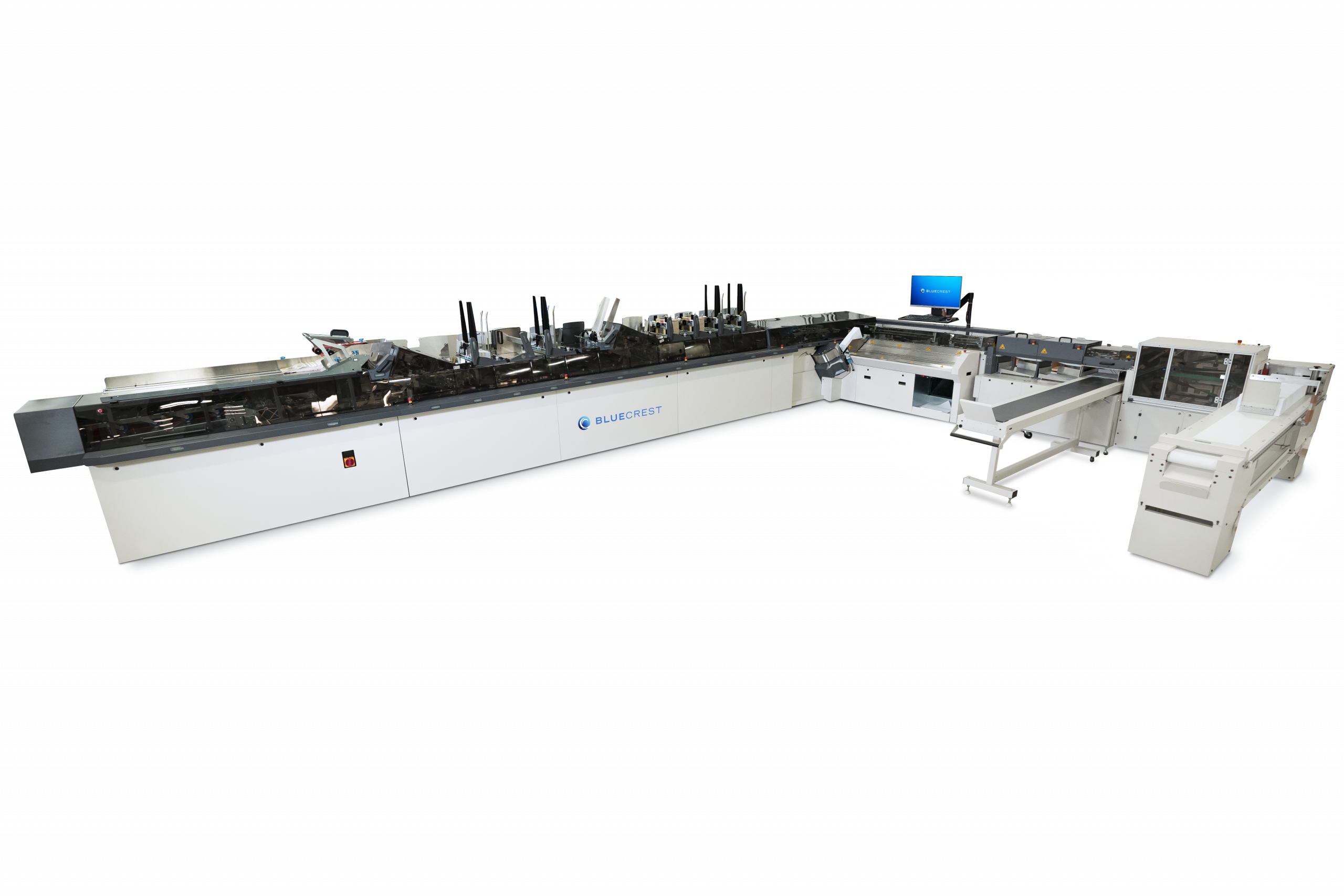

Built on the industry-leading Epic platform. Handles the widest range of direct mail applications with flexibility and ease.

- A proven platform designed for extended service cycles and greater uptime.

- Process the widest range of applications and insert at speeds up to 24K cycles per hour.

- A retrofittable modular design allowing you to easily adapt to future work. Designed for self-serviceability with lower labor costs.

Epic Direct Mail

Handles the widest range of direct mail applications with flexibility and ease. Built on the industry-leading Epic® platform, our multi-format solution boasts some of the highest net good mail pieces per hour. It can process a wide range of applications with unprecedented material tolerance, at speeds up to 24K cycles per hour. This easy-to-use solution does not require a dedicated setup technician. The system features a fully automated changeover feature, allowing you to switch between envelope formats in less than two minutes. The job recall feature makes it easy and predictable to move from one job to another.

Overview

The Epic Direct Mail has precision material control and a reduced spoilage rate due to real-time paper path corrections, lowering material costs and labor expenses associated with the make-good process on out-sorted mail. It comes read and print ready, and offers the largest range of feeding technology to handle the most challenging applications and meet stringent SLAs.

Featuring real time, integrated end-to-end tracking, Epic Direct Mail enables you to accurately and easily account for all pieces in every job. You can also quickly identify and resolve problems using the on-board diagnostic tools to reduce downtime and get your mail production up and running again. This system is designed for self-serviceability and is supported by the level of BlueCrest service that works best for your business needs.

Standard configuration:

6 feeder stations (rotary and friction) / bulk loader / read & print ready / direct connect operating system / print vacuum table / configured flats / letters & trifolds / flats conveyor & on-edge stacker

| Product Type | Industrial |

|---|---|

| Cycle speeds | . |

| Tri fold | 24k per hour |

| Half fold | 21k per hour |

| Flats | 16k per hour |

| Feeders | Rotary feeder / friction feeder / batch feeder / booklet feeder |

| Max collation thickness | 12.7 mm |

| Envelope formats | . |

| Width | Min: 178 mm Max Folded: 292 mm Max C4: 353 mm |

| Length | Min: 98 mm Max Folded: 162 mm Max C4: 259 mm |

Related products

REQUEST MORE INFORMATION

If you need more information about our products or services, please contact us and we’ll get back to you. Thanks!